cGMP Production

Home > Contract Manufacturing > cGMP Production

|

Manufacturing from lab to commercial scales. |

|

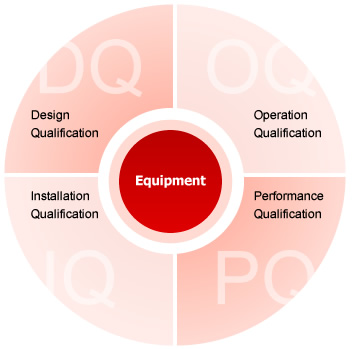

Equipment |

|

|

All our process equipments are manufactured in Taiwan, U.S, Japan or Europe.

GMP Audit List

List of GMP inspections of the site within the last 6 years

|

Name of regulatory authorities

|

Inspection date

|

Name of inspected products

|

|

US FDA

|

2018 (Nov. 05-09)

|

System based

|

|

EU-Inspection France

|

2019 (June 19-21)

|

Methocarbamol

|

|

TFDA

|

2021 (March 03-05)

|

Methocarbamol

Guaifenesin Pravastatin Sodium Trandolapril Tacrolimus Metaxalone Rapamycin Mycophenolate Mofetil Everolimus Everolimus B20 Caspofungin Acetate Fluconazole Ethyl Icosapentate Mycophenolate Mofetil HCl Sugammadex Sodium |

|

US FDA

|

2021

|

The inspection letter issued from US FDA is based on the inspection by ANSM in June 2019.

|

|

US FDA

|

2022 (Nov. 14-18)

|

Mycophenolate Mofetil (430)

|

|

US FDA

|

2024 (Apr. 8-12)

|

System based

|

|

EU-Inspection

Germany Authority |

2024 (Apr. 04-09)

|

Tacrolimus

|

|

TFDA

|

2024 (May 22-24))

|

Baricitinib

Caspofungin Acetate Difelikefalin acetate Eslicarbazepine acetate Ethyl Icosapentate Everolimus Everolimus B20 Everolimus B02 Everolimus Pre-Mix Favipiravir Fluconazole Powder Guaifenesin Methocarbamol Midostaurin Mycophenolate Sodium Mycophenolate Mofetil Mycophenolate Mofetil HCl Ozanimod hydrochloride Palbociclib Pravastatin Sodium Rapamycin Ribociclib succinate Setmelanotide Acetate Sugammadex Sodium Tacrolimus Tacrolimus (Process B) Tofacitinib citrate Trandolapril Tacrolimus SD20 |

|

PMDA

|

2024 (July 30 - Aug. 02)

|

Tacrolimus

|

Facilities / Capacity

The area of Shulin plant is 36,800 square meters with approximately 330 employees. The facilities have been audited and approved by both local and foreign authorities and major customers.

The area of Shulin plant is 36,800 square meters with approximately 330 employees. The facilities have been audited and approved by both local and foreign authorities and major customers.

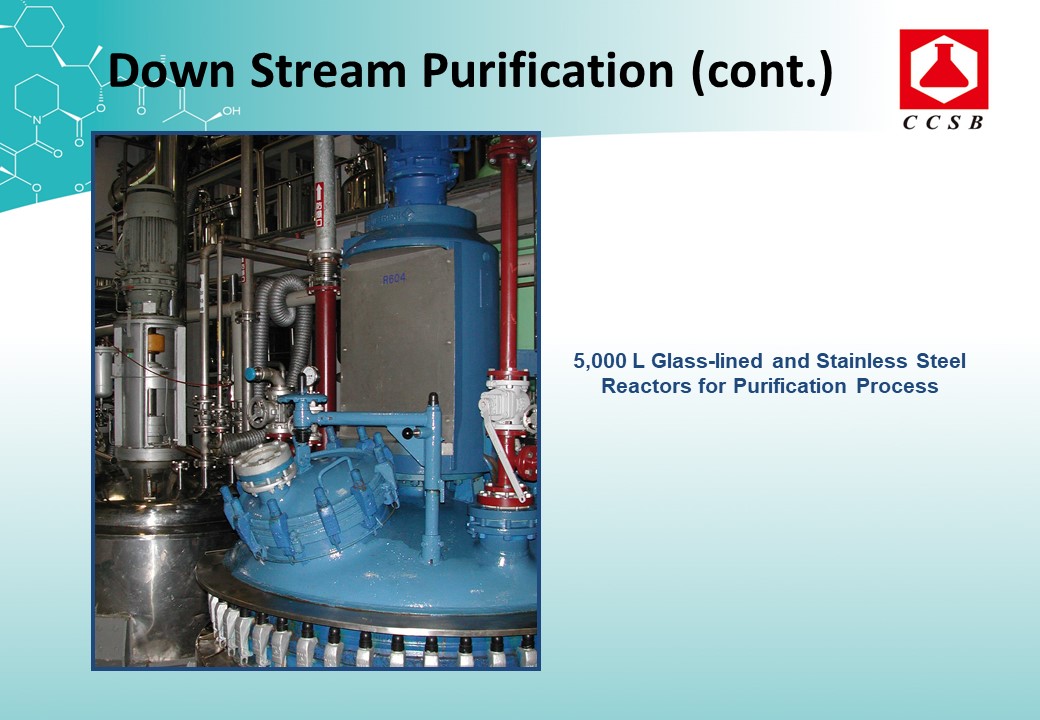

Our facilities consist of 12 areas for fermentation, purification and chemical synthesis for production ranging from kilograms to multiple tons. Fermentation capacity ranges from 350L to 30,000L. Purification and synthesis ranging from 10L to 15,000L. Reactors are made from either stainless or glass-lined. There are 7 areas for chemical synthesis, 3 areas for downstream purification and 2 area for fermentation production. Each area has its separate building with segregated clean room to perform filtration, drying, milling, sieving, packaging.

The plant operation areas includes

|

|

|

| Production Area 01 | 30L-500L | 1Kg-10Kg |

| Production Area 02 | 100L-8,000L | 10Kg-550Kg |

| Production Area 03 | 500L-7,000L | 190Kg-1,600Kg |

| Production Area 05 | 30L-7,000L | 1Kg-16Kg |

| Production Area 06 | 100L-8,000L | 2Kg-30Kg |

| Production Area 07 | 350L-30,000 | 3Kg-30Kg |

| Production Area 09 | 30L-1,000L | 0.1Kg-10Kg |

| Production Area 11 | 10L-1,000L | 0.2Kg-14Kg |

| Production Area 12 | 2000L-15,000L | 190Kg-1,200Kg |

| Production Area 13 | 50L-2,000L | 0.1Kg-3Kg |

| Production Area 15 | 30,000L | 10Kg-15Kg |

| Production Area 16 | 200L-15,000L | 15Kg-30Kg |